|

|

|

51G is a Rugged Industrial Air Motor

Designed to fit Kongsberg Gas Turbine Engines

51G Air Turbine Motor

Improving Starter Reliability for Kongsberg Gas Turbine Engines.

If your Kongsberg Gas Turbine Engine is still using a vane starter, you have no doubt encountered reliability problems. Parts that stick or swell, or simply wear out due to constant friction eventually lead to starter failure. Something no one in our industry can afford.

Replacing your vane motor starter with TDI turbine technology is a significant reliability and longevity upgrade. Turbine technology is inherently more reliable, requires no maintenance, and provides significantly longer life. The model 51G Turbine motor is specifically designed as a replacement upgrade for Kongsberg and Kawasaki engines.

Installation is Fast and Easy.

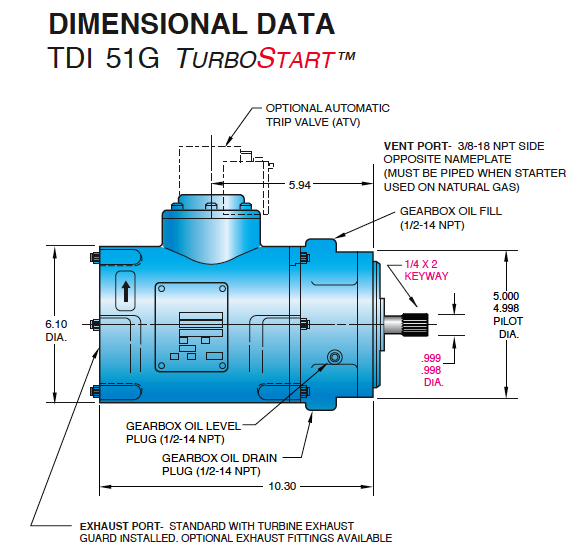

The compact 6.1” diameter size and lightweight (28lbs./12.7 kg) frame, with SAE “C” four bolt mounting flange make installation a one-man operation on your engine.

Contaminants are not a Problem AnymoreDirt, moisture, rust or other contaminants that lodge inside your vane-type starter and lead to shut down won’t get caught inside the 51G. Large air channels and TDI’s unique open gas path design allow these same contaminants to literally “pass through”. Even sour gas has no effect on the 51G.

Better Design. Better Parts. Better Reliability.

The 51G features a single stage impulse turbine coupled to an integral planetary reduction set. All parts are made from rugged, high quality steels and aluminum. There are no plastic parts. No rubbing parts. And there’s no need for messy lubricants in the supply line to clog the system. The clean simplicity of the 51G design minimizes potential problems and provides a longer maintenance-free life.

|

|

|

Versatile Nozzle Plate Puts You in Control

Gas flow control is provided using a versatile plate that houses 1 to 21 nozzles which regulate flow to the turbine wheel, allowing you to tailor the power level of the starter to application. Fewer nozzles lower the torque proportionally. The 51G is available with an optional automatic trip valve (ATV) which shuts off air flow if motor speeds begin to exceed predetermined limits.

No Drive Air Lubrication.

No Fugitive Exhaust.

The 51G operates on non-lubricated drive air. The mess, expense, and hassle of oily air lubrication systems are eliminated. Hazardous effects of fugitive emissions and the related environmental damage are also eliminated with the 51H.

Less Air

The 51G requires 33% less air to operate over competitive pneumatic models. Operating at 150 psig (10BAR), the 51G yields 165 hp (124 Kw)Three gear ratios are available: 7.5:1 ; 9.0:1 and 11.4:1.

|

|

|

|